DENSO

DENSO, a leading mobility supplier, has seen fast results from deploying six MiR250 robots in its 800,000-square foot powertrain component production facility in Athens, Tennessee.

A pilot program between its warehouse and production areas delivered results within six months, freeing six workers from pushing carts and allowing them to move to value-added roles.

The project was quickly expanded to bring components directly to line-side production for just-in-time efficiencies. Support for the robots has grown quickly among employees, with workers in other departments requesting robot support for transporting goods such as maintenance supplies and spare parts.

The company has also purchased five MiR500 robots for anticipated new business. DENSO is one of MiR’s largest global customers, with MiR robots running in four U.S. locations, three in Europe, and two in Asia.

Issue

Like most manufacturers, DENSO is always looking for ways to increase efficiency and productivity. “We knew we had a lot of people that were getting paid to move parts all day long, walking carts from one place to the other,” explains TIE engineer Travis Olinger. “But if we have people that are only conveying parts, then that’s a non-value-added activity, and we had plenty of open jobs for value-added activities within the production environment.”

He adds, “We wanted to pay people to make parts for us that makes us money, and not pay them to move parts that cost us money.”

Research showed that DENSO associates were walking up to 12 miles per day moving material between production and the warehouse, spending about 60 percent of their time pushing carts. The engineering team knew that the cost and lack of flexibility of automated guided vehicles (AGVs) couldn’t address the company’s dynamic environment that would require regular route changes. Additional challenges included narrow aisles for maneuvering and heavy metal parts to be transported. The team tested MiR autonomous mobile robots (AMRs) against competitors and were quickly impressed by their performance.

“

MiR stood out from the ability to use REST API calls, the intuitive nature of the Fleet, the ease of mapping, ease of mission creation, ease of changing locations. It was just extremely intuitive compared to the other platforms that we looked at.

Solution

MiR250 offers significant advantages, including use of REST APIs

The MiR250 had recently been introduced, and the team was attracted to its two-meters-per-second speed, the payload of 250 kilograms to handle heavy metal parts, and the ability to navigate narrow spaces. Standardizing on the MiR250 shelf-lifter and ROEQ carts allows DENSO to expand quickly into other areas using the same cart base and customizing it for each use.

The MiR robots bring significant advantages in flexibility, safety, and user-friendliness, and uniquely met other DENSO requirements as well. Olinger says, “MiR stood out from the ability to use REST API calls, the intuitive nature of the Fleet, the ease of mapping, ease of mission creation, ease of changing locations. It was just extremely intuitive compared to the other platforms that we looked at.”

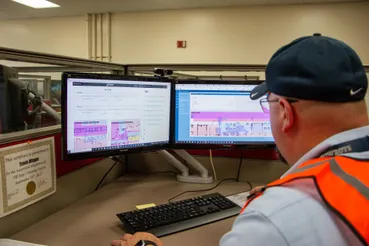

Working with MiR partner Advanced Control Solutions (ACS), DENSO was able to develop an information flow using REST API to support on-time deliveries, manage charging and proximity cues to prioritize missions, and allow associates on the floor to call for the robots. DENSO has also integrated the robot to automatically open the door in and out of a clean-room area, using the MiR I/O modules to send wireless signals to the roll-up door controller.

MiR stands out from a business-model and support standpoint

Olinger explains how MiR as a company also stood out. “MiR was prepared to support us, as Denso North America, from the numbers we were going to roll out. We looked at some companies that just didn’t have that same support structure, and didn’t have that history, and we didn’t think that they could keep up.”

He adds, “The information-sharing has been huge. It’s not just a vendor that we’ve bought something from. They have grown with us, they have become a partner, and they are instrumental in how we are now expanding.”

MiR provided a week of onsite MiR Academy training, including for DENSO employees who could be groomed into super-user roles to support the project long-term. MiR has also assigned a DENSO North America-specific contact, has created a group for DENSO on the MiR community site, and conducts monthly meetings with DENSO.

With support from MiR and ACS to ensure a smooth rollout, DENSO achieved initial setup in a day and the robots were deployed to production after about a week of testing. After that, DENSO engineers were able to manage most new deployments independently.

Immediate and ongoing results with fast ROI

DENSO’s ROI plans for projects are typically less than two years, but the indirect cost reduction from the MiR robots replacing conveyance achieved ROI in a year or less. Within six months of project launch, DENSO was able to cover all lines in the ignition plant with MiR robots and redeploy six workers to add greater value to the company. DENSO has also seen improvements in employee morale and ergonomics, as well as overall efficiency gains and a change in company culture with an automation mindset focused on streamlined processes. This represents a major change in how the engineering team designs production lines, with how components are delivered line-side as a primary consideration right out of the gate, not something that is considered later.

Olinger states, “At this point, we’ve been operating MiR robots since September 2020, we’ve run over a half million successful missions, and they have not called in sick one single day.”