Inpeco, Italy

Efficient intralogistics for Inpeco thanks to mobile robotics

The Inpeco plant in Val della Torre, Italy, deals with the production of automation systems for clinical laboratories. The company has decided to introduce a MiR200 Hook for the towing of trolleys in the production area, both for the supply of raw materials and for the transport of finished products to the packaging department.

In short

The Inpeco plant in Val della Torre, Italy, deals with the production of automation systems for clinical laboratories. The company has decided to introduce a MiR200 Hook for the towing of trolleys in the production area, both for the supply of raw materials and for the transport of finished products to the packaging department.

Inpeco is a multinational company specialized in automation for clinical laboratories and hospitals whose mission is to reduce errors in clinical trials, ensuring complete traceability of samples, to have total process control and better quality of results. Founded in Italy in 1990 as a family business, today it operates globally with its headquarters in Switzerland, and more than 750 employees across 2,500 installations worldwide.

At the Val della Torre plant, on the outskirts of Turin, automation systems are produced to order, or as customized solutions for each individual customer. The company tailors the layouts of customer automation plans, and has over 27,000 square meters of factory space of which 12,000 are dedicated to production.

Stefano Tolomeo, Head of Production at Inpeco comments: "As a manufacturer of automation solutions, the implementation of advanced technologies and the digitization of processes in our plant is a particularly relevant factor, especially from an Industry 4.0 perspective, which aims at continuous improvement of the quality and reliability of our solutions as well as the efficiency of our internal processes".

Thanks to a simple and intuitive user interface, even less experienced operators can use the robot

Re-viewing the layout in a lean-perspective

About three years ago Inpeco decided to review the processes and layout of its entire production flow from a Lean perspective. This upgrade required very efficient logistics and timely supply of the production lines, based on a call-up system from the line operators.

Specifically, the operator, once the materials to be assembled have been emptied from a trolley, he or she can call up a robot with another trolley to deliver more materials to his or her station and tow away the empty one. This process applies both to the supply of the raw materials and to the withdrawal of finished products at the operator's request once product testing has been completed.

"These movements, if handled by our staff, would have involved a full-time commitment to this activity, while our main need was to free workers from transport-only tasks, which were repetitive, of little added value and demotivating," explains Ptolemy.

“

As a manufacturer of automation solutions, the implementation of advanced technologies and the digitization of processes in our plant is a particularly relevant factor, especially from an Industry 4.0 perspective, which aims at continuous improvement of the quality and reliability of our solutions as well as the efficiency of our internal processes”

Objective: free the staff from repetitive transport tasks

After examining various options to automate internal transport in the production area, thanks to the support of Klain Robotics, distributor of Mobile Industrial Robots in Italy, Inpeco decided the MiR200 Hook was the ideal solution. The dimensions and load capacity were perfect to meet the necessary transport needs and to allow workers to engage in more value-added work.

"We were looking to automate some processes with low added value in order to be able to redirect resources to operations that are more important and indispensable for the company. We decided the first application should be the transport of raw materials from the warehouse to the production line and finished products from production to the packaging department. Thanks to the MiR robot we were able to concentrate on the most productive activities for us, always focusing on the safety of workers, the delicateness of the product and the dynamic production environment in which Inpeco is used to operating" says Roberto Ferraro, Project Manager of Inpeco.

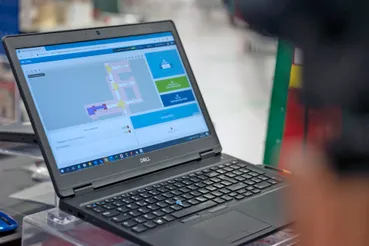

Ease of use was also a determining factor in the choice of the MiR robot. Thanks to a simple and intuitive user interface, even less experienced operators can use the robot, always having the opportunity to monitor and manage missions. With the MiR robot, warehouse operators can now devote themselves more to higher value activities such as picking, loading materials in automated storage areas and avoiding wasting time on tasks that simply involve moving goods.

"Another reason that has proved decisive in the choice of the MiR robot is its ability to move along corridors where it shares space with factory personnel or other means of goods handling. The robot is able to detect obstacles, even when they are in motion and adjust its path accordingly so as to achieve the goal of its mission. The MiR robot saved us the space that a traditional solution would require, given that such a solution doesn’t allow for the space to be used for other purposes", says Tolomeo.

In the Inpeco production area, 16 different objects of varying length, from 1m up to 2.5m, are moved using the MiR200 Hook

Rapid implementation and operational efficiency

Production orders are prepared from stock by picking up the material and loading up trolleys of variable weight, up to 500 kg. Once the job is completed, the trolley is made available for transport by the MiR robot.

When a job is finished in production, the operator activates the call-up software by scanning a QRCode assigned to his or her work area to request the delivery of a trolley with materials for the next job and the collection of the empty trolley currently at the station. This way, the destination of the robot's mission is registered as the location of the operator who made the call-up. The software also automatically retrieves the correct production order from the management system, making all this on-screen information available and allowing the warehouse managers to know which trolleys are being collected by the robot.

Once all the assembly phases of the product have been completed, the finished article must be transported to the packaging department. The operator then registers on the management system the end of the process and packets of information are automatically sent to the robot software, including the size of the article to be moved and its initial position on the map.

Currently in the Inpeco production area, 16 different objects of varying length, from 1m up to 2.5m, are moved using the MiR200 Hook.

From robot to colleague

"When the MiR robot was integrated into the plant, the workers were mainly curious and a little skeptical but, already after a few hours of activity, the skepticism disappeared and there was enthusiasm to see just how user friendly the application was. When everyone could see the robot in operation and the advantages it offered in terms of time savings and therefore efficiency levels, as well as the fact that they could delegate to the robot various repetitive and low-value tasks, the MiR officially became a valuable team member. Today, Inpeco workers interact and collaborate with the MiR robot as if it was just another colleague," says Ptolemy.

To decide what name to give the robot, the company held a poll in which all the employees participated, who were now very interested and happy to have such an unusual "colleague".

The robot, renamed Robin, has therefore contributed not only to the optimization of Inpeco's internal logistics but also to the security of the production area. During its journey, the MiR robot makes several detours, travelling along the corridors that delimit the production operator stations. Each time it enters the corridors, as well as turning and automatically hooking up a trolley, the robot communicates via flashing lights and sounds that alert operators to its arrival. In addition, during its journey, thanks to 3D cameras and precision sensors, the robot always places the trolley it is towing in the center. When it encounters an obstacle, be it a person or a forklift truck, the MiR robot stops and assesses whether an alternative route is available, always in consideration of the trolley. This ensures maximum safety along the way, eliminating the risk of accidents.

A future of logistics automation

"To date, our MiR200 Hook robot is used in a specific area of our production departments but we were able to immediately appreciate the benefits of mobile robotics. However, we must consider that we are in phase 1 of our project that provides for the use in 2021 of the MiR200 to also supply another production area with the same logic and with the same benefits." continues Ptolemy.

Inpeco predicts that the implementation will be very easy and quick since it will only be necessary to identify the areas on the factory map where the robot will have to deliver the raw materials and withdraw the finished products, while the system will inherit all the configuration logics already implemented previously.

"At the initial stage of the project we had estimated that we would get a return on the initial investment in a maximum of 2 years and to date we can say that this will be achieved even a few months earlier" concludes Ptolemy.

In addition, the company plans to integrate a new robot with another type of interface that allows, in addition to towing materials, the handling of individual boxes (600X400mm or 400x300mm) from the warehouse to the bench operator and vice versa.