Optimizing Workflows with the MiR1200 Pallet Jack

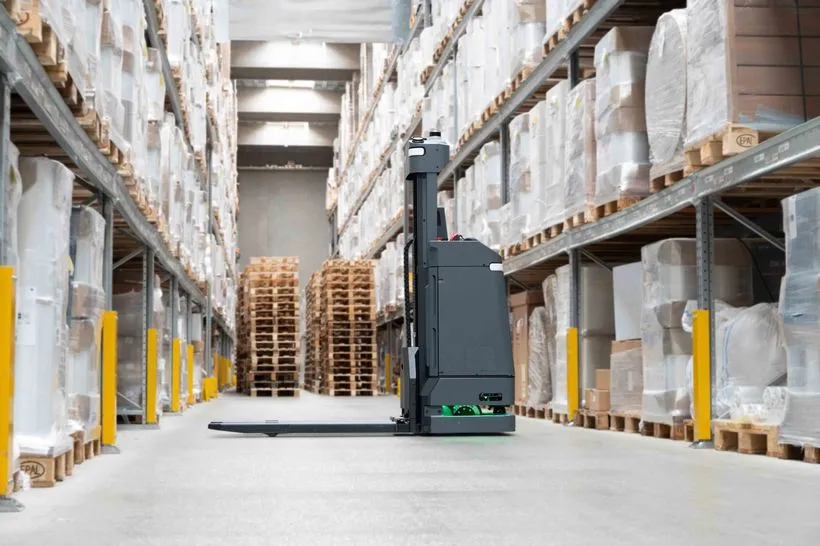

In the pursuit of efficiency and safety in pallet movement operations, companies are continually seeking innovative solutions to optimize their workflows. The MiR1200 Pallet Jack emerges as a promising tool in this endeavor, offering advanced technology tailored for industrial material handling.

This agile robot operates continuously, effortlessly navigating tight spaces to optimize logistics efficiency and ensure timely pallet delivery without the need for additional infrastructure. With its advanced features, the MiR1200 Pallet Jack enhances throughput, reducing pick-and-place cycle times and leading to increased productivity with faster movement of goods up to 1200 kg at 1.5 m/s. Moreover, its long-lasting battery capacity and opportunity charging feature ensure uninterrupted performance, relieving employees from heavy lifting and monotonous tasks. Designed to comply with the latest safety standards, the MiR1200 navigates safely around people and obstacles, making it a reliable and trusted asset in any industrial setting.

Learn how the MiR1200 Pallet Jack transforms typical workflows, unlocking new levels of efficiency and productivity in material handling operations.

5 Typical Workflows that can be automated efficiently with MiR1200 Pallet Jack

Long Haul Transports Optimization

In many warehouses, long haul transports where pallets need relocation, can be labor-intensive and time-consuming when done manually. With the MiR1200 Pallet Jack, these tasks are streamlined and optimized. The robot autonomously navigates through the facility, efficiently transporting goods and empty pallets over long distances. By automating these processes, businesses can significantly reduce labor costs and improve overall operational efficiency.

Empty Pallet Management Operations

Managing empty pallets is a critical aspect of warehouse operations, whether it involves feeding production lines or removing pallets from them to keep a lean environment. The MiR1200 Pallet Jack excels in this area by autonomously handling the transportation of empty pallets. It can collect empty pallets from production areas and deliver them to designated storage locations or recycling stations. In the same way, it can retrieve pallets from storage and deliver them to production lines as needed. This automation optimizes the flow of materials, reduces congestion, and minimizes downtime.

Steady Operational Flow with Predictable Takt Times

For processes requiring a steady operational flow with predictable takt times, the MiR1200 Pallet Jack offers unparalleled efficiency. It’s able to follow predefined routes and schedules, ensuring that materials are transported precisely when needed, maintaining a smooth and consistent workflow. Whether it's delivering components to assembly lines or transporting finished goods to staging areas, the MIR1200 Pallet Jack enhances productivity by eliminating delays and bottlenecks.

Finished Goods End-of-Line Operations

At the end of production lines, efficient handling of finished goods is essential for timely delivery and distribution. The MiR1200 Pallet Jack can facilitate this process by swiftly transporting finished goods from end-of-line areas to staging areas or pallet wrapper stations. Its advanced navigation capabilities allow it to navigate through crowded spaces with ease, optimizing the flow of goods and reducing the risk of congestion. By automating end-of-line operations, businesses can improve throughput and meet customer demands more efficiently.

Pallet transport from Receiving Dock to Staging Area

From the moment goods arrive at the pallet entry point to their final destination in the staging area, the MiR1200 Pallet Jack ensures seamless and efficient transportation. Upon arrival, the robot identifies and collects pallets efficiently using it’s AI-based pallet detection, navigating through the facility to the designated staging area. Along the way, it avoids obstacles and adjusts its route dynamically to optimize efficiency. By automating this entire process, the MiR1200 Pallet Jack minimizes manual labor requirements and maximizes throughput, ultimately enhancing the overall efficiency of material handling operations.

See different workflows that can be automated by MiR’s fleet of AMRs