Manufacturing Robots

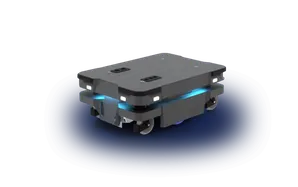

In the ever-evolving landscape of manufacturing, MiR's Autonomous Mobile Robots (AMRs) are revolutionizing the way production processes are carried out.

Unlike traditional AGVs in manufacturing, which are limited to fixed routes, MiR's AMRs bring adaptability, intelligence, and efficiency to the production floor.

With AMR manufacturing, businesses can expect a seamless integration of robots that can navigate complex environments, adapt to changes, and work alongside human employees.

What are the uses of manufacturing and production robotics?

Material Handling

AMRs can transport raw materials, components, and finished products between different sections of the manufacturing facility.

Assembly Line Support

They can be integrated into assembly lines to supply parts and assist in assembly processes.

Inventory Management

AMRs can be used for inventory tracking and management, ensuring that stock levels are maintained.

Inspection and Quality Control

Equipped with sensors and cameras, AMRs can carry out inspections and quality control checks.

Packaging and Palletizing

AMRs can automate the packaging process and arrange goods on pallets for shipment.

What are the uses of manufacturing and production robotics?

Manufacturing and production robotics have a plethora of applications that can transform the efficiency and productivity of industrial processes. MiR's AMRs, in particular, are known as collaborative robots in manufacturing due to their ability to work harmoniously alongside human workers. Here are some of the ways in which AMRs can be utilized:

Material Handling: AMRs can transport raw materials, components, and finished products between different sections of the manufacturing facility.

Assembly Line Support: They can be integrated into assembly lines to supply parts and assist in assembly processes.

Inventory Management: AMRs can be used for inventory tracking and management, ensuring that stock levels are maintained.

Inspection and Quality Control: Equipped with sensors and cameras, AMRs can carry out inspections and quality control checks.

Packaging and Palletizing: AMRs can automate the packaging process and arrange goods on pallets for shipment.

Machine Tending: They can load and unload machines, ensuring that production equipment is utilized efficiently.

How manufacturing robots can take over many of the manual tasks

Human Collaboration. Perhaps the most significant aspect of AMRs is their ability to collaborate with humans. They can be programmed to work in tandem with human employees, taking over repetitive and physically demanding tasks. This not only enhances productivity but also allows human workers to focus on more complex and creative tasks.

“

We wanted staff to get back onto the production line and drive efficiency. By bringing the MiR robots on-site, we freed up six full-time staff members to produce more, and make the line more efficient

By integrating MiR's AMRs into manufacturing and production processes, businesses can achieve a higher level of efficiency, safety, and productivity. The collaborative nature of these robots ensures that human workers are supported, rather than replaced, making them an invaluable asset in the modern manufacturing environment.

MiR makes it possible for anyone to program an Autonomous Mobile Robot, ensuring a smooth transition into an automated production system. This not only streamlines the manufacturing process but also optimizes productivity and reduces operational costs. The incorporation of MiR AMRs is a game-changer for businesses looking to embrace the future of manufacturing.

What robots are used in manufacturing?

In the manufacturing industry, robots such as AGVs and AMRs are used to automate internal transportation and logistics. AGVs in manufacturing have been traditionally used for moving materials along fixed routes. However, AMR manufacturing is revolutionizing the industry with its flexibility and intelligence.

Unlike AGVs, AMRs can navigate autonomously, avoiding obstacles and optimizing routes in real-time. This makes AMRs more adaptable and efficient, especially in dynamic manufacturing environments where agility is key. The choice between AGVs and AMRs ultimately depends on the specific needs and goals of the manufacturing process. Learn the key differences between AMRs and AGVs.

Why are autonomous mobile robots better for manufacturing?

Increased Productivity: AMRs can work around the clock, ensuring continuous production and thereby increasing productivity.

Cost Reduction: By automating repetitive tasks, AMRs can reduce labor costs and operational expenses.

Flexibility: AMRs can easily adapt to changes in the production environment and can be reprogrammed for different tasks.

Safety Improvement: AMRs are equipped with sensors and cameras that allow them to safely navigate around obstacles, reducing workplace accidents.

Efficient Material Handling: AMRs can transport materials between different points in the production line, ensuring timely availability of resources.

Reduced Workload on Employees: By taking over repetitive and physically demanding tasks, AMRs allow human employees to focus on more complex and value-adding activities.

Quick Return on Investment (ROI): The efficiency gains and cost savings provided by AMRs often result in a quick ROI.

Scalability: As production needs grow, additional AMRs can be easily integrated into the system.

Improved Employee Morale: By reducing the physical strain on employees, AMRs can lead to higher job satisfaction and morale among the workforce.

Potential for Reduced Workweek: With increased efficiency and productivity, companies can explore the possibility of a reduced workweek for human employees without compromising output.

Choose MiR for safe and flexible manufacturing robots

Flexibility and Adaptability: MiR's manufacturing robots are highly flexible and adaptable, capable of navigating dynamically changing environments.

Ease of Integration: MiR robots can be easily integrated into existing workflows without the need for extensive modifications to the infrastructure. This is a cost-effective solution for businesses looking to implement production robotics.

Safety: MiR robots are designed with safety in mind, ensuring that they can operate in environments with human workers without posing risks. This is a crucial feature for robots in manufacturing.

Customizable Top Modules: MiR offers customizable top modules that can be added to the robots for specialized tasks.

Efficiency and Productivity: MiR robots are known for their efficiency and can significantly boost productivity by taking over repetitive and time-consuming tasks.

Quick ROI: MiR robots offer a quick return on investment, often within a year, making them a financially sound choice for businesses.

Wide Range of Payload Capacities: MiR offers robots with a range of payload capacities to suit different needs, from the compact MiR100 to the heavy-duty MiR1350.

Find your return on investment

Supercharge your manufacturing operations with AMRs. Cut costs, streamline supply chains, enhance safety, minimize downtime, create an attractive workplace, and respond swiftly to market demands.

Calculate your ROI by choosing your robot:

250kg payload

600kg payload

1350kg payload