Factory Robots

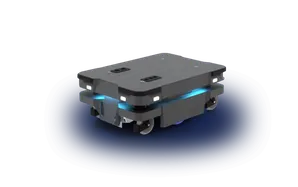

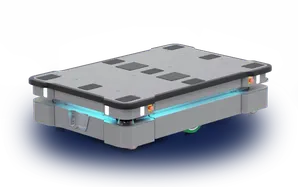

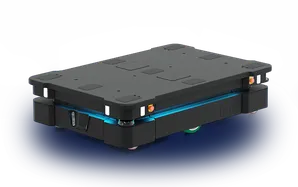

In an increasingly competitive market, factories are turning to Autonomous Mobile Robots (AMRs) to streamline operations and enhance productivity.

Our diverse range of AMRs is designed to cater to various factory needs, with the added advantage of customizable add-ons and applications through MiR Go. This flexibility allows our robots to adapt to your unique factory environment, making them an integral part of your productivity-enhancing strategy.

The benefits of using robots in factories

Increased Efficiency

Our AMRs streamline material handling and transportation, reducing cycle times. By automating repetitive tasks, the AMRs reduce labor costs.

Enhanced Safety

MiRs factory robots are equipped with sensors and cameras to safely navigate around obstacles and reduce workplace accidents.

Scalability & Flexibility

They can be easily scaled up or down to meet changing production demands. Unlike traditional fixed automation, MiRs robots can be reprogrammed for different tasks and routes.

Labor Allocation

Freeing up human workers from mundane tasks allows them to focus on more complex and value-adding activities.

Customization

They can be equipped with various attachments and integrated with other systems for specialized tasks.

Why use Autonomous Mobile Robots in factories?

Robots in factories are not here to replace human workers but to assist and augment their capabilities. AMRs excel at tasks that are repetitive, time-consuming, or physically demanding.

Autonomous mobile robots from MiR are proving to be invaluable assets in various types of factories including automotive manufacturing, electronics, food and beverage processing, pharmaceuticals, textiles, plastics, metal fabrication, chemical processing, paper, and furniture manufacturing.

What are robots used for in factories?

AMRs are adept at handling material transportation, inventory management, and other repetitive tasks, thereby alleviating the workload on employees and allowing them to focus on more complex and critical functions in the automated factory.

The benefits of using robots in factories

The benefits of integrating autonomous mobile robots like MiR robots into factory operations are manifold:

Increased Efficiency: Our AMRs streamline material handling and transportation, reducing cycle times.

Cost-efficient: By automating repetitive tasks, the AMRs reduce labor costs.

Enhanced Safety: MiRs factory robots are equipped with sensors and cameras to safely navigate around obstacles and reduce workplace accidents.

Scalability: They can be easily scaled up or down to meet changing production demands.

Flexibility: Unlike traditional fixed automation, MiRs robots can be reprogrammed for different tasks and routes.

Labor Allocation: Freeing up human workers from mundane tasks allows them to focus on more complex and value-adding activities.

Customization: They can be equipped with various attachments and integrated with other systems for specialized tasks.

How much does the average Mobile Robot cost? A cost-effective investment

Investing in a robot for factory environments from MiR is not just a purchase; it’s a strategic and cost-effective investment. With flexible financing options available through MiR Finance, acquiring an AMR is more accessible than ever.

The rapid return on investment (ROI), coupled with the long-term benefits of increased efficiency and productivity, makes MiR’s robots an indispensable asset for any forward-thinking factory.

Find your return on investment

Supercharge your manufacturing operations with AMRs. Cut costs, streamline supply chains, enhance safety, minimize downtime, create an attractive workplace, and respond swiftly to market demands.

Calculate your ROI by choosing your robot:

250kg payload

600kg payload

1350kg payload